Mechanical joining cell for VDL VDS with ABB robots

For VDL VDS in Hapert (Noord-Brabant, Netherlands) we've made a machine which joins parts of a step grille. Together with ABB and VDL VDS and Liam van Koert, we've created the article below about this installation, which can also be read in edition three of Robot Magazine 2022. The document can be downloaded in its original format at the bottom of this page.

VDL VDS maximises benefits of an increasingly robotic production floor

Front step for truck drivers

Innovation is all around, even in truck grilles. A customer of VDL VDS in Hapert recently developed a foldable version of such a grille, which has a double function as a front step. This allows drivers to clean their windscreen without a ladder, giving them a safe view of the road. A big innovation created with little effort? Not exactly. Drivers will undoubtedly clean their windows with ease, as they don't have to arrange a ladder as a front step anymore. But producing these front step grilles is quite a big job, which required three companies to build the two robot cells needed to deliver the grilles in large quantities at a constant, high quality.

VDL VDS Technische Industrie is one of the VDL companies in Hapert which focusses on high quality metalworking. This producer of complex metal parts for e.g. the automotive, equipment, aerospace, medical and construction industry has been part of the VDL group since 1981. Their machine park includes mechanical and hydraulic presses ranging from 100 to 800 tonnes, but has been expanded with a (spot)weld, laser cutting and assembly department in the past decennia. Mother of all presses is the impressive, fully automatic 800 tonnes Schuler, which elevated pressing to a continuous process.

Craftsmanship

Daan Roovers, head of Process Engineering at VDL VDS, explains that punching seemingly simple parts such as a grille, is anything but easy. In fact, developing the right punches, welding cell with welding jig and finally the assembly cell, required a lot of expertise. VDL VDS's expertise primarily consists of getting the most out of their 23 pressing stations. While beholding some punches in the factory, one can imagine this requires specific and technically advanced knowledge.These "nearly machines" are an ingeniously synchronised assembly of precision parts. They look complex, even to a technical minded person receiving some explanation about the way they work. Roovers explains that the "what", "when" and "on which press" also belong to the process. The advanced logistic planning, so to speak, in which not every punch is suitable for every machine, while one wants to operate as many machines at the same time as possible.

Welding

In addition to the punches, the VDL VDS factory also houses various welding stations. For example 16 spot welding machines, two 3D laser cutting/laser welding machines, various dedicated automations and 13 welding cells. This final category also includes the ABB welding cell for the grille which was recently added. VDL VDS has chosen to outsource the design of this cell to ABB because of its complexity and their experience with Automotive/Tier 1 projects. While in the Benelux lesser known, because of the preference of working with system integrators, ABB delivers in specific cases also complete robot welding cells from their factory in the Czech Republic. "We are increasingly using ABB robots, not exclusively though. We try to set a standard for robotisation. Besides the pleasant cooperation with the ABB team and the sound products this has the advantage of having one single contact for service and it makes the planning of maintenance easier. On the other hand it's nice to have a familiar control interface for the various production lines for the operators and technical service. In the specific case of the welding cell, it was nice to be able to order a complete FlexArc K cell with two IRB 1600's and all accessories such as the workpiece positioning, welding torch and safety systems. The advanced welding jigs, three for three variations of products, are he only customer specific part. But ABB also made sure these were made and installed based on the designs created with our input."

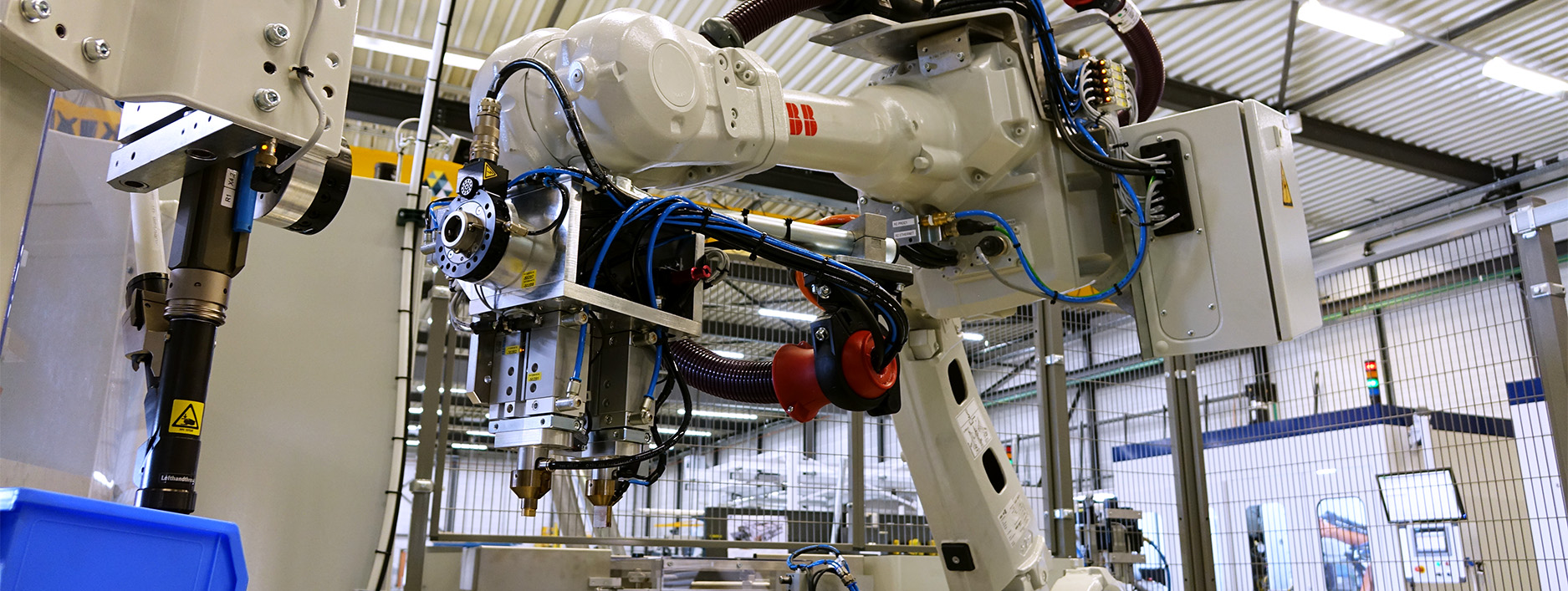

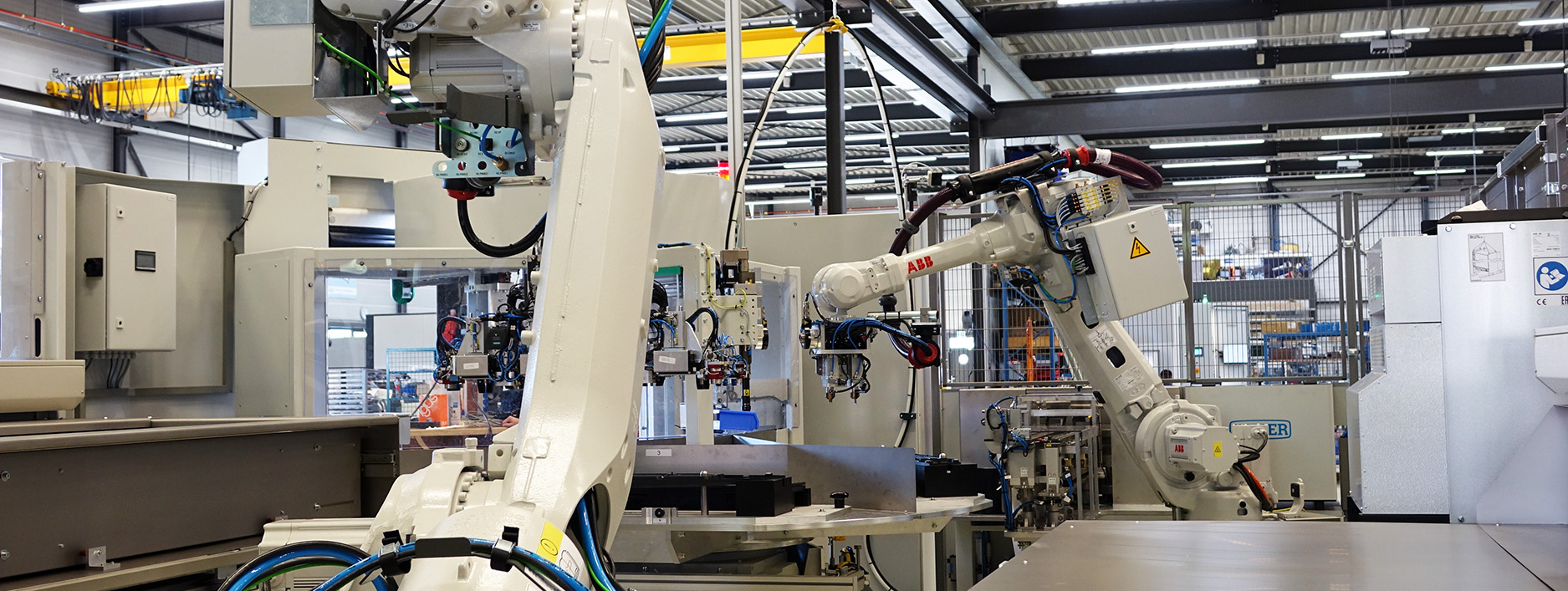

Assembly cell with two robots

As Sales Engineer at Manders Automation, Rob Haerkes was closely involved in the development of the assembly cell for assembling the front grilles. He explains: "In this cell, the metal and plastic parts of the grille are connected. Once welded and subjected to various treatments, the metal parts of the grilles are transported to the assembly cell in special crates. Here, they are placed on the turntable by the input and output robot (an IRB 6700). Because of the way in which the plastic parts are delivered and the variety of part types, we decided to have them placed manually by operators. They also place the fastening clips on the parts, which then turns to the assembly robot. This robot (an IRB 4600) assembles various fastening parts. Finally, the now complete grille is turned to the first robot (IRB 6700), which picks it up and neatly discharges it from the cell after placing protective sheets to avoid paint damage."

Why VDL VDS chose Manders Automation for the design and construction of this cell? "At Manders Automation, we're specialised in various assembly and joining techniques. Besides knowdlege about automation, you also need the proper process knowledge to succeed in the field in which we operate. As the last cell we've created for VDL VDS has been working properly for quite some time to everyone's full satisfaction now, we were also granted this next project. We know both ABB and VDL VDS well and the lines of communication are short. This makes it easy to align our expertises. For which challenges our own expertise proved itself particularly useful? In this project, it was mainly in dealing with the shape stability of the plastic and for achieving the desired cycle times. That means optimising robot paths and processes, for example by executing tasks parallel to each other or in a different order. Of course, safety is always a priority as well. In the end, a SafeMove solution using PROFIsafe was chosen for the safety of this cell."

Strategic robotisation

The assembly cell is managed by a central PLC which also directs the robot controllers and provides an OEE (Overall Equipment Effectiveness) system with data.This system is linked to an ERP system developed by VDL. Daan Roovers explains that this collective system provides insights into the OEE of the cell, which is rising continuously. "At the moment, we're working on the optimization of the output of robots and operators. With supervision of a process engineer, we create mainly small batches for half a year. In this way, we can smooth out any disruptions in this phase. Next is the ramp up and after that, we'll go on at full speed. From that moment on, we'll create the desired numers and quality with two shifts and the cell will be officially released for production. If you imagine we've started this project at the end of 2018, you can conclude it takes a lot to produce a new assemblied product such as a grille. However, that doesn't scare us. Moreover, we've got the taste of it. We, VDL VDS, want to diversify so we're not just dependent on punching, but are also able to process plastics for example. So this front step grille is a nice step for us as well."

Rob Haerkens:

"At Manders Automation, we're specialised in various assembly and joining techniques. Besides knowdlege about automation,

you also need the proper process knowledge to succeed in the field in which we operate. As the last cell we've created for VDL VDS

has been working properly for quite some time to everyone's full satisfaction now, we were also granted this next project."

You can read the article in the Robot Magazine lay out here (in Dutch)